Vacuum Mold Casting Process . It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. in this introductory guide, we give you an overview of the vacuum casting process, materials used, considerations, and key benefits and limitations of this form of manufacturing. this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention.

from electricalworkbook.com

in this introductory guide, we give you an overview of the vacuum casting process, materials used, considerations, and key benefits and limitations of this form of manufacturing. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone.

What is Vacuum Forming? Process, Applications, Products & Advantages

Vacuum Mold Casting Process vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone. vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone. this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. in this introductory guide, we give you an overview of the vacuum casting process, materials used, considerations, and key benefits and limitations of this form of manufacturing.

From www.researchgate.net

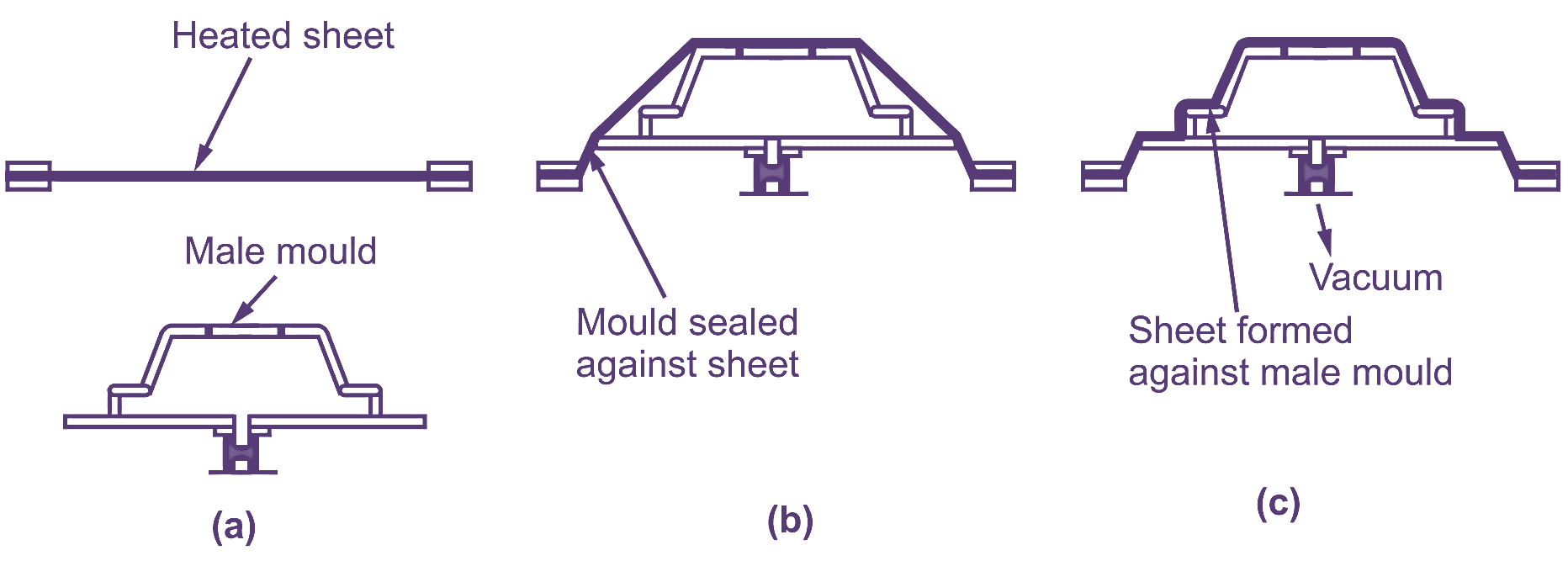

5 Vacuum forming with the female mould (a) and male moulds (b Vacuum Mold Casting Process It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. in this introductory guide, we give you an overview of the vacuum casting process, materials used, considerations, and. Vacuum Mold Casting Process.

From hlhrapid.com

Vacuum Casting Process Overview, Benefits & Limitations Vacuum Mold Casting Process this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast. Vacuum Mold Casting Process.

From www.youtube.com

Vacuum Forming Process Working Applications ENGINEERING STUDY Vacuum Mold Casting Process vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two. Vacuum Mold Casting Process.

From prototechasia.com

How Does the Vacuum Molding Process Work? • Prototech Asia Vacuum Mold Casting Process this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. vacuum casting is a. Vacuum Mold Casting Process.

From www.thelibraryofmanufacturing.com

Vacuum Permanent Mold Casting Vacuum Mold Casting Process vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. this article aims to shed light on vacuum casting, a crucial process. Vacuum Mold Casting Process.

From plasticmouldingsnorthern.co.uk

How To Vacuum Form Plastic Mouldings Northern Vacuum Mold Casting Process vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone. in this introductory guide, we give you an overview of the vacuum. Vacuum Mold Casting Process.

From www.slideserve.com

PPT Chapter 13 MultipleUseMold Casting Processes PowerPoint Vacuum Mold Casting Process in this introductory guide, we give you an overview of the vacuum casting process, materials used, considerations, and key benefits and limitations of this form of manufacturing. vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone. The liquid materials used for vacuum casting are elastomers such. Vacuum Mold Casting Process.

From www.engineersedge.com

Sand casting Vacuum Molding VProcess Engineers Edge www Vacuum Mold Casting Process this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. vacuum casting is a. Vacuum Mold Casting Process.

From engineeringlearn.com

16 Types of Moulding [Explained with Complete Details] Engineering Learn Vacuum Mold Casting Process It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. vacuum casting is a. Vacuum Mold Casting Process.

From www.manufacturingguide.com

Vacuum forming Find suppliers, processes & material Vacuum Mold Casting Process this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using. Vacuum Mold Casting Process.

From www.marmaxdesign.com

Guide to vacuum casting MarMax Vacuum Mold Casting Process vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. in this introductory guide, we give you an overview of the vacuum casting process, materials. Vacuum Mold Casting Process.

From www.youtube.com

Vacuum Molding Expandable Mold Casting Processes. YouTube Vacuum Mold Casting Process vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. in this introductory guide, we give you an overview of the vacuum. Vacuum Mold Casting Process.

From electricalworkbook.com

What is Vacuum Forming? Process, Applications, Products & Advantages Vacuum Mold Casting Process The liquid materials used for vacuum casting are elastomers such as plastic and rubber. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. It involves. Vacuum Mold Casting Process.

From www.thelibraryofmanufacturing.com

Vacuum Casting or Vprocess Vacuum Mold Casting Process in this introductory guide, we give you an overview of the vacuum casting process, materials used, considerations, and key benefits and limitations of this form of manufacturing. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. It involves creating a mould of the. Vacuum Mold Casting Process.

From stock.adobe.com

thermal vacuum molding process. Obtaining volumetric parts from plastic Vacuum Mold Casting Process It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. in this introductory guide, we give you an overview of the vacuum. Vacuum Mold Casting Process.

From www.thelibraryofmanufacturing.com

Vacuum Casting or Vprocess Vacuum Mold Casting Process this article aims to shed light on vacuum casting, a crucial process in plastic molding that merits attention. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. vacuum casting is a. Vacuum Mold Casting Process.

From dexumachine.en.made-in-china.com

Foundry Vacuum Process Casting Molding Machine Production Line China Vacuum Mold Casting Process vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone. vacuum casting is a process in which a liquid material is drawn into a silicone mold whilst using a vacuum, to create complex components. The liquid materials used for vacuum casting are elastomers such as plastic and. Vacuum Mold Casting Process.

From www.thelibraryofmanufacturing.com

Vacuum Casting or Vprocess Vacuum Mold Casting Process in this introductory guide, we give you an overview of the vacuum casting process, materials used, considerations, and key benefits and limitations of this form of manufacturing. The liquid materials used for vacuum casting are elastomers such as plastic and rubber. vacuum casting is a manufacturing process similar to injection molding where urethane resin is cast in a. Vacuum Mold Casting Process.